Precision Air Conditioning under brand “STULZ” is an Air Conditioning that is used to control. Accurate temperature and humidity by using energy efficiency or known as green technology. Precision Air Conditioning is designed for IT room where it requires constant room set point 24/7 and also for other applications such as laboratory, Tape Room, Test Room, etc.

STULZ is manufactured in Germany by ISO9001:2008 factory that covers entire production line including design, production, testing, and service and that’s how STULZ achieves global recognition. STULZ features include:

- Electrical Commuted Fan Technology (EC Fan) or direct driven fan without belt

- Hotgas Reheat which is the process of bringing back wasted heat and reuse in the room

- Electronic expansion valve (EEV) which controls flow of refrigerant

- CW Standby Management technology which is the chilled water type

Contact the SITEM team on SITEM’s official LINE account @sitem or fill out the form at the end of this page for more information or any inquiries to SITEM’s products and services.

Air Conditioning Concepts for Individual Solutions

- Cooling capacity 18 kW – 240 kW

- 7 sizes

- 8 cooling systems

- EC technology

- Direct and Indirect Free Cooling

- All standard refrigerants

- Unlimited versatility; wide range of options

MiniSpace EC

For small and medium sized server rooms

- Cooling capacities 5 kW – 25 kW

- 600 x 600 mm footprint up to approx. 15 kW

- 1000 x 810 mm footprint up to approx. 26 kW

- EC fan

- 3 cooling systems (A, G, CW)

- Upflow, downflow, Displacement

- Diverse range of options

- Free Cooling option

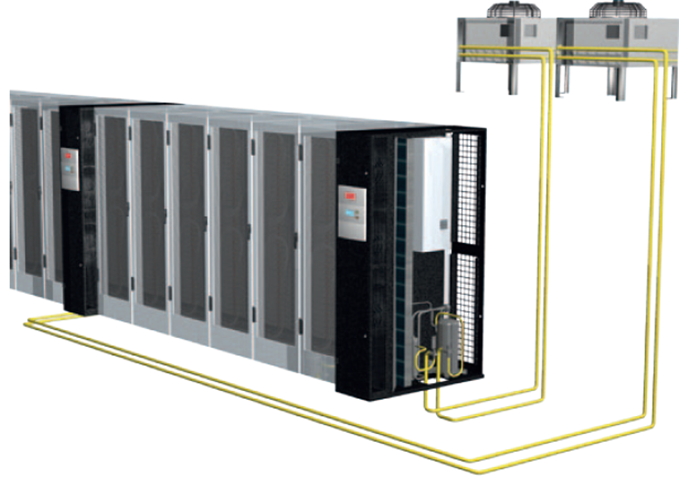

CyberRow

Row Cooling

- Direct Rack Cooling

- Innovative horizontal air Conduction

- 4 cooling system (A, CW, G, GE)

- Up to 56 kW water-cooled

- Up to 36.5 kW compressor-cooled

- Up to 36.6 kW with Indirect Free Cooling

- Standalone A/C unit

- EC compressor

- In widths of 300, 400 and 600 mm

Airflow Management for hot spot

AirBooster, AirBooster Pro and Air Modulator

- Precisely designed for standard raised floor panels

- Compatible with any server racks

- Easy installation, operational in minimal time

- Electricity supply: 230 V / 50 Hz / 1 Ph; lower inrush current = UPS

- Temperature and pressure control (Air Booster)

- Infinitely variable adaptation of the fan speed up to 2500 CMH (Air Booster/PRO)

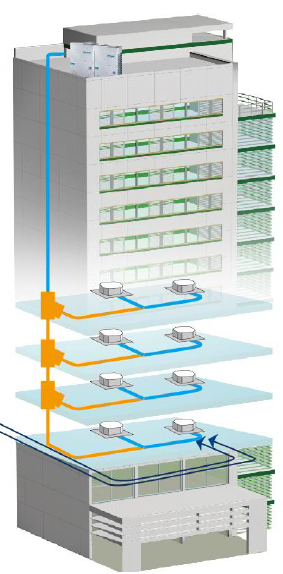

VRV / VRF Air Conditioning System

VRV (Variable Refrigerant Volume) or Variable Refrigerant Flow (VRF) Systems

Are air conditioning systems that have the ability to change the amount of refrigerant depending on load and air conditioning. While there are many air conditionings running, the control unit will order to release a large amount of refrigerant into the system. When less air conditionings are working, the system will control enough amount of refrigerant for running the air conditioning. This system is suitable for installation in buildings which the area of CONDENSOR UNIT is limited because condenser unit can be connected to several fan coil units in the building. It may be located in the same or another floor. The operation of the fan coil unit is independent, so it can control the temperature accurately.

At present, Thailand has installed air conditioners at almost every building. Most of the power usage is from the air conditioning system. So, innovative air conditioning system has developed and invented. The most popular air conditionings installed in the building are VRV or VRF Air Conditioning System.

There are 4 types of control devices which are.

- Remote and wired Individual Control

- Indoor unit control and outdoor unit monitor for Centralized Control

- BMS Gateway Controller has 4 types of data transmission device namely BACNET, LONWORKS, MODBUS and KNX

- Intelligent Control is the smart system operating through Network

Benefits of system installation

This system is a technology that directly controls the amount of refrigerant delivered by install the refrigerant controller at the indoor unit. So, it can precisely control temperature and it can save up to 40% of electricity compared to other air conditioning systems. It also improves air quality by minimizing air humidity and other processes as well helping users to be in comfortable conditions at all times.

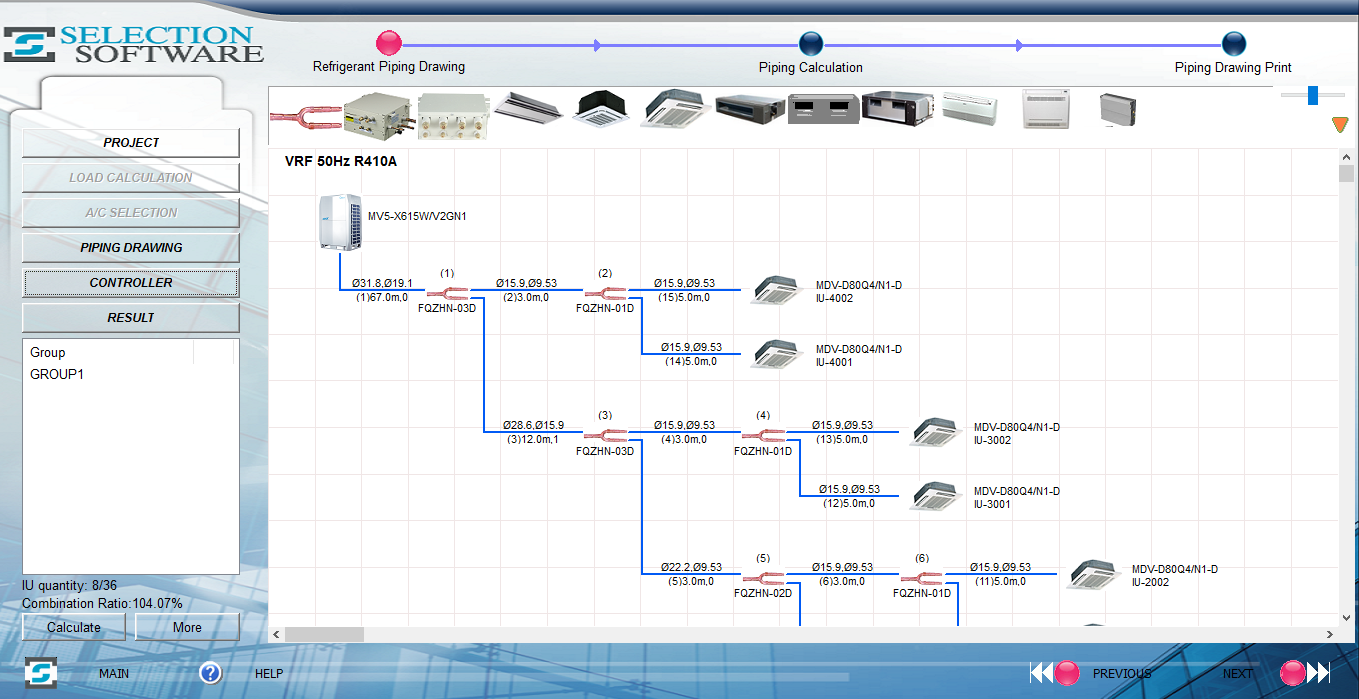

Design

First, choose the indoor unit size to suit each room. Then, select the outdoor unit size from the refrigeration level. Then, design the refrigerant pipeline and use the program to calculate the refrigerant pipe size as shown.

How to calculate BTU

BTU = Room area (Width x Length) x Factor

Factor

700-800 for a bedroom or room with less heat.

800-900 for living room or rooms with moderate heat.

900-1000 for office, exercise room or room with high heat or high ceiling.

1000-1200 for shop or large office.

If the ceiling is higher than 2.5 meters, or there are many people or computers, add 5% of BTU.

SITEM provides and installs air conditioners that are designed to focus on energy saving or known as Green Technology, which is suitable for use in accordance with the current IT technology or Data Center that must work 24 hours a day.

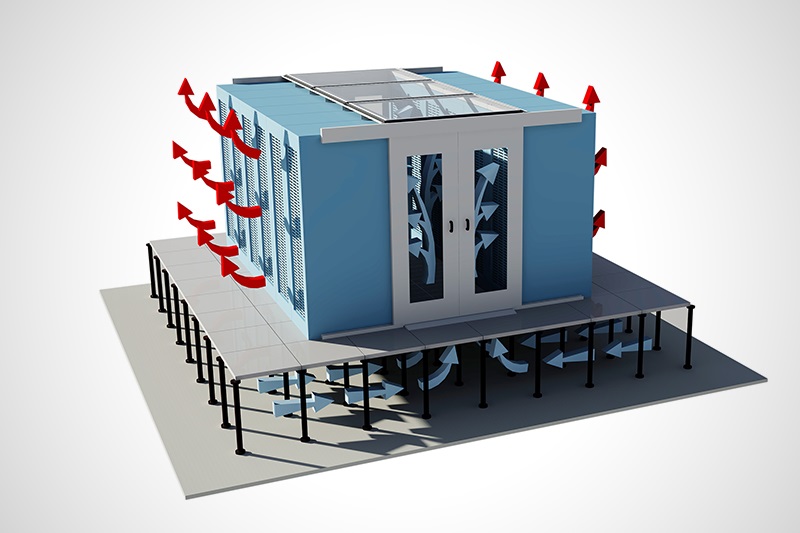

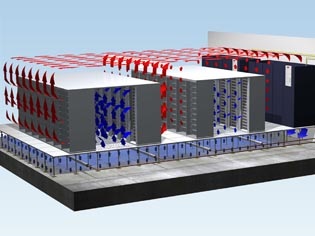

Cold Aisle Containment System in Data Center

Today, many data center choose smaller server equipment with equal or higher performance. However, the equipment that manufacturers try to make it smaller, also has high weight and high-power consumption. When the smaller equipment has high power consumption, one thing that cannot be avoided is the higher heat load in each rack due to the fact that one rack can be fitted with more equipment. Therefore, effective cooling system is necessary for data center. The system that will improve the performance of the air conditioning system is Cold Aisle Containment system.

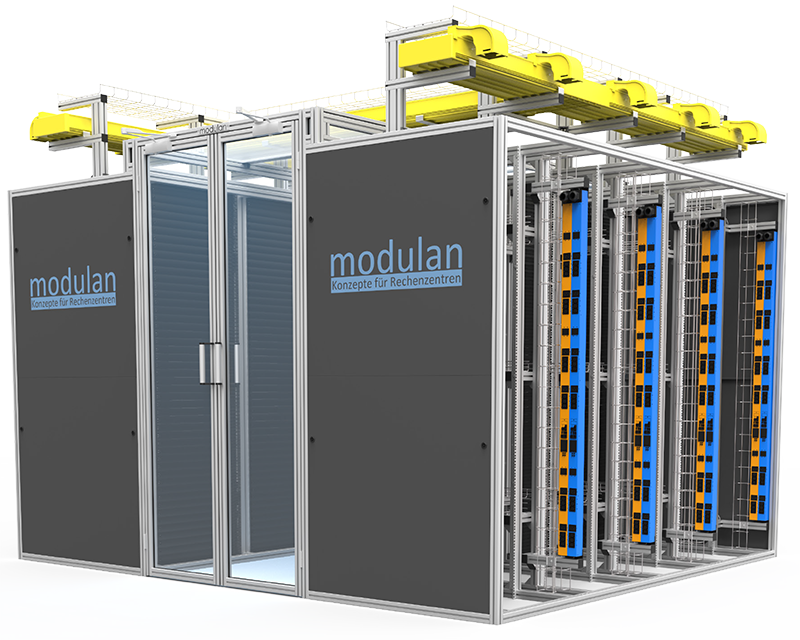

What we see on a regular basis in every Data Center is the rack cabinet which can be considered as important for visitor. The most common rack cabinets in the market are look alike and the function sometimes are not answer the purpose and not enough.

Modulan Solutions for IT-Infrastructures is an alternative to the application and is the novelty of the rack cabinet industry, which the size and shape can be customised .The material is good grade aluminum, which makes the weight per cabinet, if compared with the common rack, is much reduced but not the strength. This makes installation easier. The connection is able to change easily. Its door, how it open and its height are designed to suit the needs of customers and for best performance

Sometimes, changes of position or moving rack are difficult to do and and need a lot of time. Some people give up and buy a new one, which use more budget. Modulan can answer the need about moving and installation issues. It can be dismantled and easy to reinstall.

The technique of Hot and Cold Axis in accordance with ASHRAE TC 9.9 air conditioning standard is to separate hot and cold air in the data center in order to reduces the mix of hot and cold air. So, the air conditioning system can work effectively and electricity consumption in data centers is reduced.

The 100% separation of hot and cold air technique is commonly used in data center in oversea. Cold Aisle Containment is mostly installed to isolate and trap cold air from hot air. It is the most energy efficient system in the data center.

Features of Cold Aisle Containment

1. Can be resized – can be resized to fit existing infrastructure to maximize the use of the rack as the demand increases.

1. Can be resized – can be resized to fit existing infrastructure to maximize the use of the rack as the demand increases.

2. Can be configured. – There is separated heat and cooling system. This increases the reliability of the data center.

3. Efficient – Cold Aisle Containment allows the hot air to flow back to the CRAC directly and increase the efficiency by operating at higher temperature difference (ΔT).

4. Reliability – The Cold Aisle Containment system optimizes the cooling system available throughout the data center, utilizing the asset and reducing operating costs.

5. Flexible installation – It does not require you to modify the existing cabinet location and can also be installed on other manufacturers’ cabinets.

And another type is Hot containment, which is the wind trap in the cooling system. The aim is the to prevent a mixing between hot and cold air. However, the installation is quite limited depending on height of installation or the distance between the two racks, which can be affected by the heat from other racks.

Contact the SITEM team on SITEM’s official LINE account @sitem or fill out the form at the end of this page for more information or any inquiries to SITEM’s products and services.