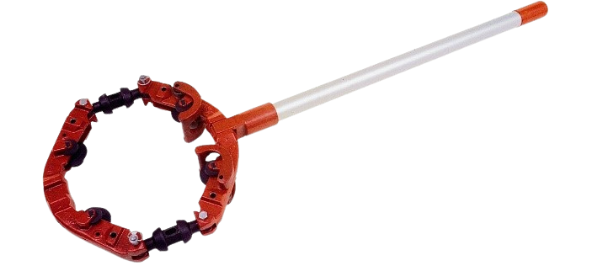

In the past, no matter where the pipe system is located, installation and assembly of the pipe requires welding that generates heat, spark and dirt. Nowadays, technology has made the welding process no longer necessary.

The benefits of the weldless piping technology are:

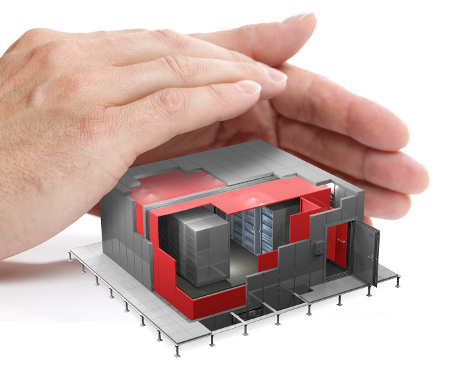

- No heat and flame in important areas.

- No electrical wave generated from high current in welding or glare from occured sparks, which can damage sensitive or fragile electronic devices.

- No need for workers with welding skills. Even highly experienced welder may have an error in welding.

- No welding test is required. Some of the test requires X-ray or chemical.

- Works can be done everywhere that is humanly accessible. Unlike the welding that requires to connects wires and gas pipe with an equipment. If there is no power source nearby, the equipment preparation can turn into a big task.

- Use less people. Only one person can finish it.

- Faster than welding.

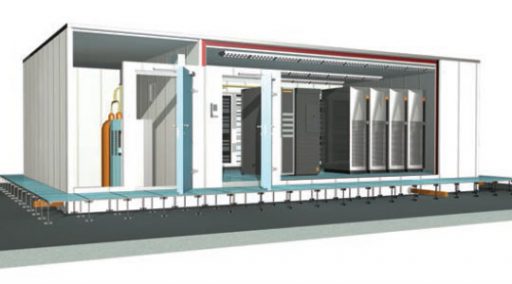

- New pipe can be prepared directly from the factory. As a result, the quality and cleanliness of the pipes can be controlled.

- Save higher cost than welding.

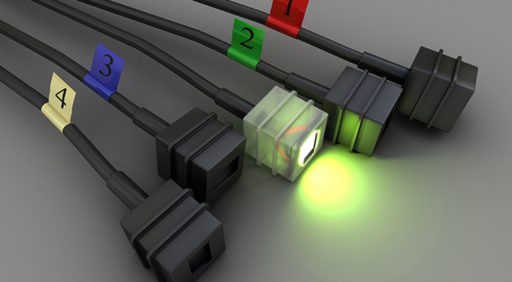

- Only one equipment can be used for all types of pipes. Unlike welding, tools and materials vary according to the type of pipe.

- The chances of human error are so small. Because the installation tools are designed to be easy to use and reduce the chance of errors.

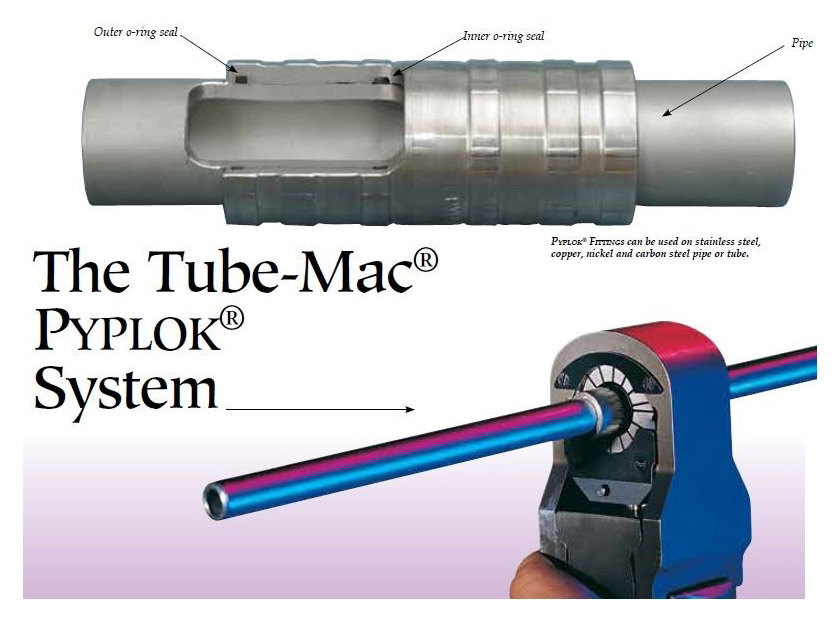

PYPLOK technology that we choose is a patent product from Canada. It is certified by world class standards such as ASME, ANSI, DNV, ABS, BV, CCS, NK, and LLYOD.

Many leading companies in the world have chosen PYPLOK to replace the welding of pipe system and have a history of using PYPLOK for nearly 20 years, ensuring that PYPLOK has long lifetime equal to or longer than the pipe itself.