พื้นยกสำเร็จรูป Raised Floor

ในห้อง Data Center

Raised Floor ระบบพื้น 2 ชั้น ใช้ป้องกันการแตกร้าวหรือรั่วซึมของโครงสร้าง เช่น ดาดฟ้า, ถังน้ำ, ห้องเครื่อง ป้องกันและกำจัดไฟฟ้าสถิตย์ซึ่งเกิดขึ้นมาจากคอมพิวเตอร์ เมื่อคอมพิวเตอร์หลายๆตัวกำลังทำงานและจะช่วยรักษาเสถียรภาพของคอมพิวเตอร์

พื้นยกสำเร็จรูป Raised Floor คืออะไร?

พื้นยกสำเร็จรูป (Raised Access Floor) คือ ระบบพื้น 2 ชั้น ที่นิยมใช้ในอาคารสูงและอาคารสาธารณะ มีลักษณะยกพื้นสูงขึ้นเพื่องานตกแต่งภายใน และแก้ไขปัญหาพื้นอาคารเก่าเช่น งานต่อเติม ซ่อมแซมอาคารเก่า ใช้ป้องกันการแตกร้าวหรือรั่วซึมของโครงสร้าง เช่น ดาดฟ้า, ถังน้ำ, ห้องเครื่อง ป้องกันและกำจัดไฟฟ้าสถิตย์ซึ่งเกิดขึ้นมาจากคอมพิวเตอร์ เมื่อคอมพิวเตอร์หลายๆตัวกำลังทำงานและจะช่วยรักษาเสถียรภาพของคอมพิวเตอร์

โดยพื้นที่ระหว่างพื้นยก (Raised Floor) และใต้พื้นยก (Sub Floor) ทำหน้าที่ เหมือนกับท่อส่งลม หรือ Air Plenum มีฉนวนยางพร้อมแผ่นอลูมิเนียม สำหรับป้องกันการสูญเสียพลังงาน และการกลั่นตัวของไอน้ำที่บริเวณ Sub Floor รวมถึงขาตั้งของพื้นยก ในพื้นที่ระหว่าง Raised Floor และ Sub Floor มักมีการเดินสายไฟ อีกทั้งยังได้มีการนำ Foamed Cement เข้ามาเป็นตัวช่วยในการเพิ่มการรับน้ำหนัก นอกจากนี้ที่บริเวณขอบของพื้นยกยังได้มีการใช้วัสดุ PVC ที่สามารถทนต่อไฟฟ้าสถิตย์ได้เป็นอย่างนี้ พื้นยกจึงนิยมใช้กับห้อง Server ที่มีสายไฟหรือสายเคเบิ้ลจำนวนมาก

ในปัจจุบันมีการใช้งานอย่างแพร่หลาย เช่น สำนักงานศูนย์คอมพิวเตอร์ (Data Center) ห้องควบคุม (Control Room) ห้องคลีนรูม (Clean Room) ห้องเซิร์ฟเวอร์ (Server Room) และพื้นของอาคารอัจฉริยะที่มีงานระบบท่อมาก ต้องซ่อมบำรุงหรือปรับเปลี่ยนบ่อยๆ

คุณสมบัติของแผ่นพื้นยกสำเร็จรูป Raised Floor สำหรับห้อง server

แผ่นพื้นยกสำเร็จรูป Raised Floor ต้องเป็นรูปสี่เหลี่ยมจตุรัส ขนาดต่อแผ่น 60 x 60 ซม. ต้องทำด้วยเหล็กปั๊มขึ้นรูป ภายในอัดแน่นเต็มด้วยสารซีเมนต์ (light-weighted Cement) ซึ่งสามารถป้องกันความชื้นและความร้อนได้ดี เคลือบด้วย Epoxy ป้องกันการกัดกร่อน ผิวปิดของแผ่นพื้นยกสำเร็จรูปด้านบนเป็นชนิด High Pressure Laminate (HPL) วัสดุของแผ่นพื้นยกต้องเป็นชนิดไม่ติดไฟ และเป็นวัสดุ Class A คุณสมบัติของแผ่นพื้นยกต้องสามารถรองรับ Design Concentrated Loads ได้ไม่น้อยกว่า 450 กิโลกรัม และมีค่า Ultimate Loads ได้ไม่น้อยกว่า 13,350 นิวตัน เพื่อให้มีประสิทธิภาพการรองรับน้ำหนักได้ดี และต้องวางอยู่บนขาตั้ง (Pedestal) และคานรับพื้น (Stringer)

มาตรฐานของแผ่นพื้นยกสำเร็จรูป Raised Floor

แผ่นพื้นยกสำเร็จรูปต้องผ่านการทดสอบ Ultimate, Rolling, และ Impact Loads ตามขั้นตอนมาตรฐานของสถาบัน CISCA หรือ ASTME84-98

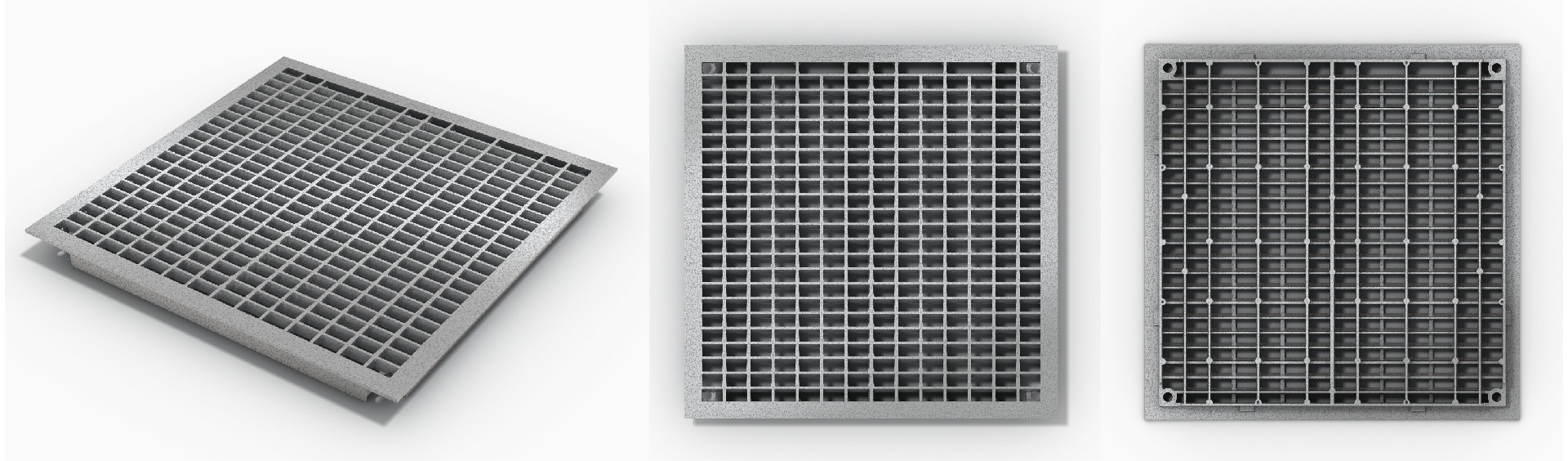

แผ่นระบายลมเย็น Perforated Raised Floor

แผ่นพื้นยกระบายลมเย็นมีขนาด 60×60 ซม. วัสดุเป็นตะแกรงอลูมิเนียมและช่วยป้องกันไฟฟ้าสถิต สามารถระบายอากาศได้ 64 % ของพื้นที่แผ่น ผ่านมาตรฐาน CISCA โดยมีการออกแบบให้มีทิศทางการระบายอากาศเข้าหาตู้ RACK ได้ตลอดทั้งหน้า Rack เพื่อช่วยให้สามารถส่งลมเย็นให้กับอุปกรณ์ได้อย่างมีประสิทธิภาพ

แผ่นปรับปริมาณลมหรือแผ่นควบคุมปริมาณอากาศ Damper

วัสดุเป็นอลูมิเนียม สามารถปรับการไหลของอากาศได้ตั้งแต่ 0 – 100 % โดยไม่ต้องถอดแผ่นระบายอากาศ perforate ออก และสามารถปรับใบ blade ได้อย่างอิสระ 3 zone เพื่อช่วยควบคุมปริมาณลมที่จ่ายจากเครื่องปรับอากาศไปยัง Rack เพื่อลดการจ่ายลมไปยังตำแหน่งที่ไม่ต้องการช่วยให้ประหยัดพลังงาน

Leave a Reply